Day 1: start of project.

hurdles to overcome:

manifold studs seized- soek with wd40

really dumb position of A/c compressor bolts

pre-installation- the victim

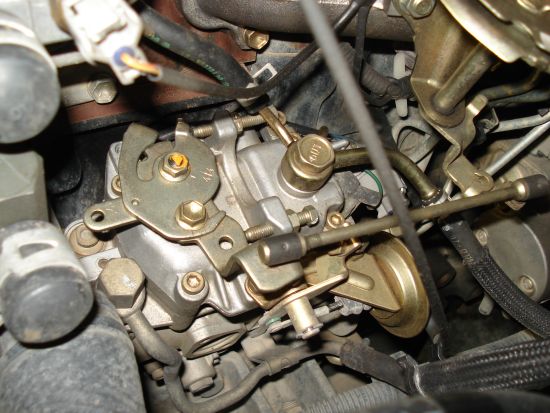

the original3L diesel pump:

the donor pump off the 2LT. this pump will be scrapped for the diesel aneroid. Toyota was smart in their design. the top of the pump can come straight off and bolt on to the stock pump without a single modification. if you look carefully at the two pumps, you can see the four bolts to be remove for the swap. what is an aneroid? this is what advances the pump to supply more fuel when the turbo is in use. it is a simple vacuum system. many person simply advance the fuel screw, but this causes black smoking at low revs, and burns more fuel.

after installation engine bay pic: (will post more pics soon of the actual install)

turbo, manifold and one set of piping in.

odds and ends, after one hr of installation

All parts for this project were sourced from a 2LT 2.4 toyota diesel engine. the 3L was designed to be turboed. don't let anyone fool you. some dead give aways that toyota meant to turbo this engine are the fact that turbo manifold bolt holes are pre drilled on the head already, vacuum hose hard lines leading straight to where the turbo unit is are already there, straight swap of diesel pump aneroid onto the 3L pump. same hold true for the 2L naturally aspirated engine.

now as you can see, i didnt connect the turbo to the intake, since i am missing these parts. any help me out here will be appreciated.

tomorrow:

hook up blood (oil) to the turbo. the existing line on the turbo fell exactly on an oil vein on the block. direct bolt up.

hook up pyrometer and boost guage

source turbo timer

temporilly adjust diesel screw, pending installation on aneroid by YAV autoserv

laters